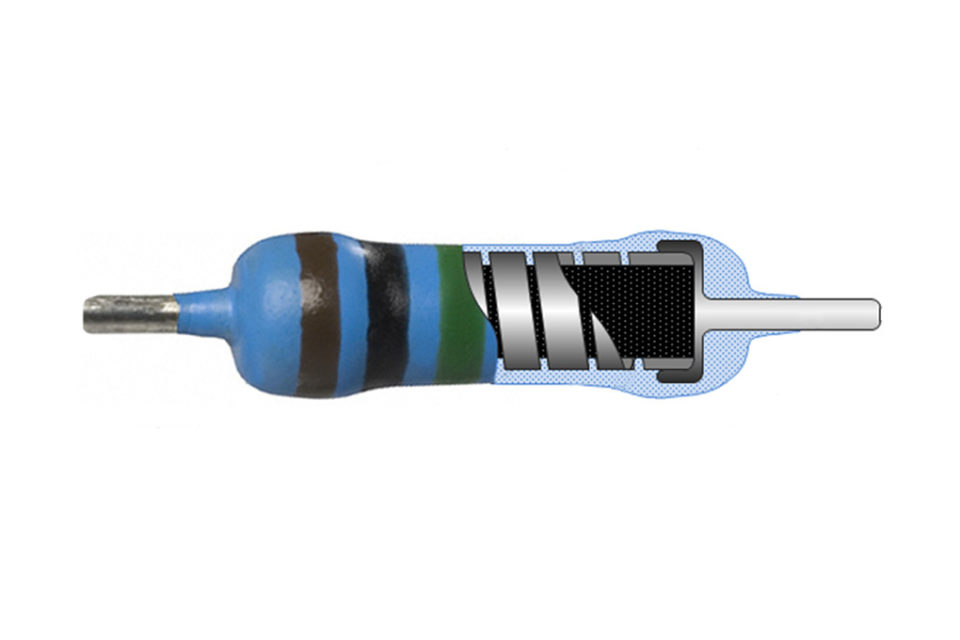

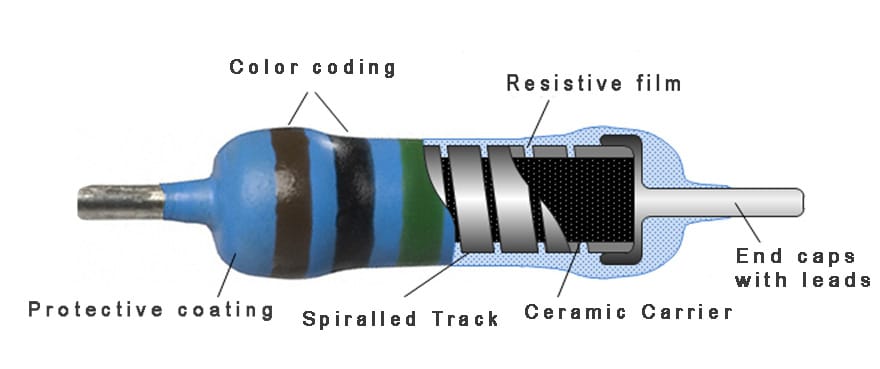

Use metal film resistors. They are amongst the most common types of axial resistors.

metal film vs metal foil resistors is important information accompanied by photo and HD pictures sourced from all websites in the world. Download this image for free in High-Definition resolution the choice "download button" below. If you do not find the exact resolution you are looking for, then go for a native or higher resolution.

Don't forget to bookmark metal film vs metal foil resistors using Ctrl + D (PC) or Command + D (macos). If you are using mobile phone, you could also use menu drawer from browser. Whether it's Windows, Mac, iOs or Android, you will be able to download the images using download button.

A carbon film resistors performance usually fluctuates more than a metal film resistors.

Metal film vs metal foil resistors. By yuval hernik. There is a value of thickness for a given alloy that is best for temperature characteristics but the range of resistances associated with this thickness is limited. Right now i have a voltage divider for each channel in my amp bypassing gain pots fixed voltage divider of 0 20k ohm.

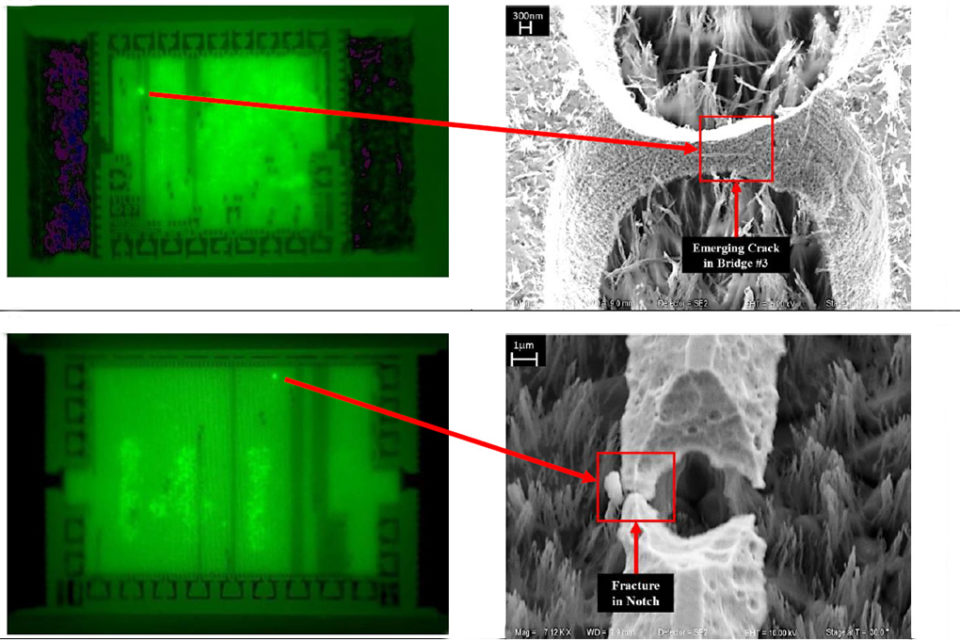

Because of their small mass of metal thin film resistors are also much more susceptible to self etching in the presence of moisture. In most literature referrals to metal film usually it is a cylindrical axial resistor. I am using a metal film 1 tolerance resistor right now for each channel each measuring exactly 200k ohms on my multimeter.

At any rate with such a low resistance and the location of the circuit it makes little difference between metal or carbon film. Strengths and weaknesses of common resistor types. They are more economical to produce that wirewound or foil resistors.

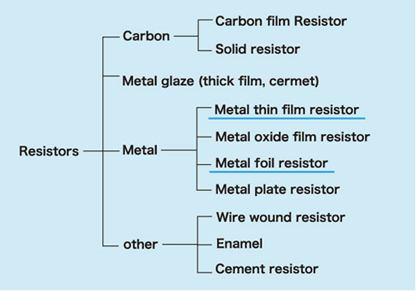

Other film type resistors are carbon film and thick and thin film resistors. Metal film resistors are best if the application involves fast rise times microseconds or high frequencies in mega hertz. 01 uv 0c.

Lol i specify carbon film there not for its sound its because metal film resistors less than 10 ohms in that size are very hard to find. New foil resistors have a thermal emf of. The colors brown and red represent a more stable resistor value and indicate a metal film resistor.

Metal film resistors militaryestablished reliability hermetically sealed mil prf 55182 qualified precision type rnr characteristics e and c resistors fixed 20. Thin film resistors these resistors are made by depositing a thin layer of metal on a ceramic base. When cost is the only consideration use metal films.

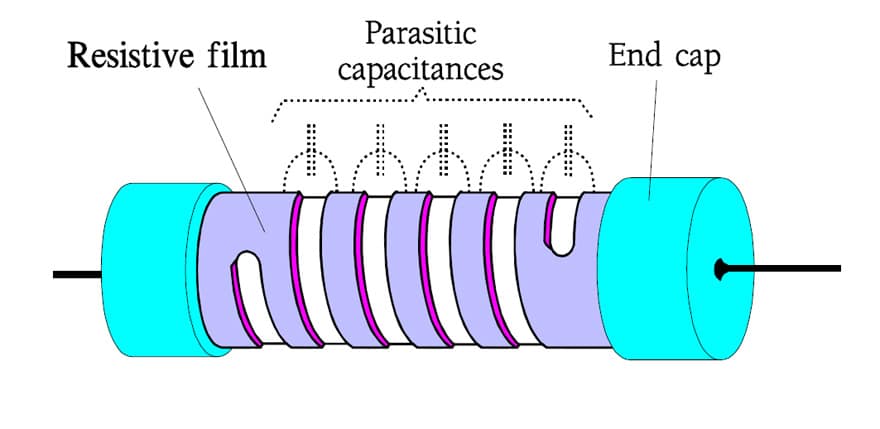

Metal film resistors have a thin metal layer as resistive element on a non conducting body. The tolerance band which stands farthest to the right on resistors printed with four and five bands is the fifth band on resistors with six color bands. Thin films can produce a higher resistance per given area than wirewound or bulk metal foil resistors.

Thick film networks also are created by screening pastes of mixed ceramic and metal particles which are then fired and solidified into cermet resistors. Whats the difference between foil and thin film resistors. The key deciding factor between wirewound or metal film precision resistor technology is depends on the application.

Resistors Non Wirewound Resistors Metal Film Foil And

Resistors Non Wirewound Resistors Metal Film Foil And

Understanding High Precision Resistor Temperature

Understanding High Precision Resistor Temperature

Resistors Non Wirewound Resistors Metal Film Foil And

Resistors Non Wirewound Resistors Metal Film Foil And

Strengths And Weaknesses Of Common Resistor Types Ee Times

Strengths And Weaknesses Of Common Resistor Types Ee Times

2 Manufacturing Methods And Characteristics Of Thin Film

2 Manufacturing Methods And Characteristics Of Thin Film

Small 1 Watt E96 22 Ohm Metal Film Resistor Metal Foil

Small 1 Watt E96 22 Ohm Metal Film Resistor Metal Foil

Resistors Non Wirewound Resistors Metal Film Foil And

Resistors Non Wirewound Resistors Metal Film Foil And

Vishay Foil Resistors 1kw 0 6w Metal Foil Resistor 0 01 1ppm C Y00621k00000t9l

Vishay Foil Resistors 1kw 0 6w Metal Foil Resistor 0 01 1ppm C Y00621k00000t9l

Strengths And Weaknesses Of Common Resistor Types Ee Times

Strengths And Weaknesses Of Common Resistor Types Ee Times

The Value Of Tcr In High Precision Resistor Selection

The Value Of Tcr In High Precision Resistor Selection

Metal Film Resistors Explained Applications Advantages Availability Etc

Metal Film Resistors Explained Applications Advantages Availability Etc